“Quality means doing it right when no one is looking.” -Henry Ford

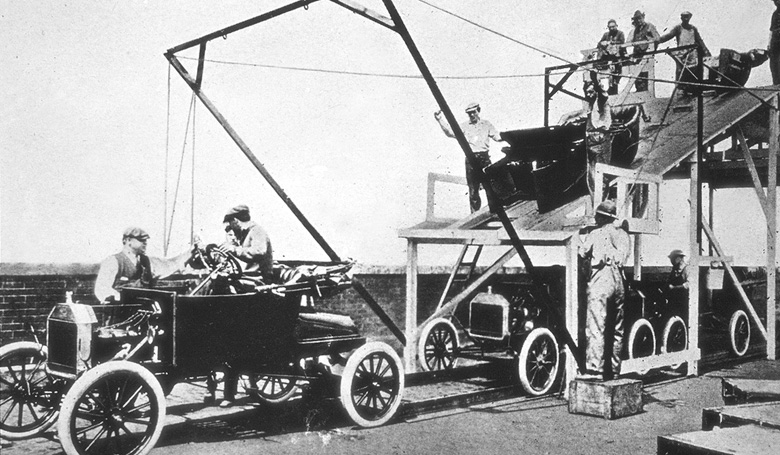

On April 1st, 1913, the first mass production assembly line began producing Model T's at the Ford Motor Company factory in

Since Henry designed the assembly to have interchangeable parts other companies started using a mass assembly line during their manufacturing process. Other companies who began using assembly lines were able to produce three times more than before. With the wide spread use of the assembly line, many products became more affordable due to the speed of manufacturing and increased amount of production. With vast amounts of products available and more affordable, it improved the overall quality of life.

The Mass Production Assembly line is still in use today. Most Manufacturing companies use the assembly line to make their product(s) because it is much easier than making them by hand. Because of the assembly line, the things we want to by are cheaper and avalable to a more diverse population.